- No products in the cart.

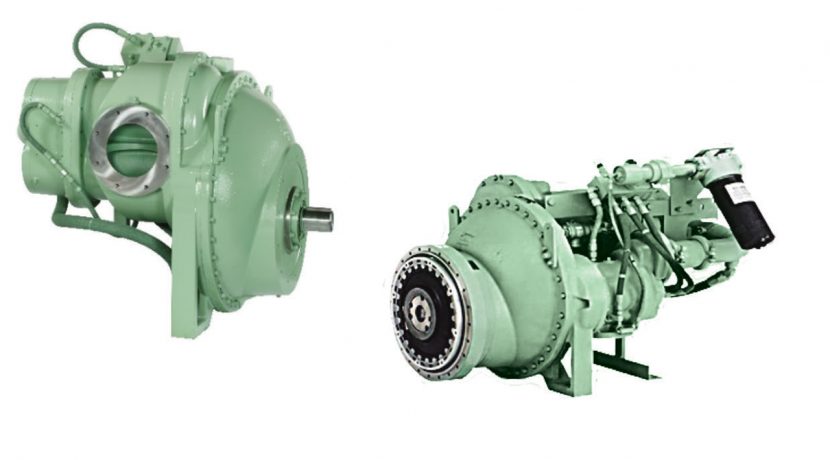

20/12 Series 600-900/350 Drill Compressor

20/12 Series 600-900/350 Drill Compressor

Two Stage Rotary Screw

The Sullair high pressure two stage rotary screw drill compressor delivers capacities and pressures from a range of 600 cfm at 350 psig or 17 m3/min at 24 bar to 900 cfm at 350 psig or 25.5 m3/min at 24 bar. The Drill air-end is designed with a inlet control system and drive adapter to match up with drive choices. Multiple gear ratio’s with matched internal volume ratio’s dials in specific capacities and pressure for optimum performance.

20/12 Series 600-900/350 Features

- Bare shafted drill airend

- 2-Year warranty

Rotors

Precision ground asymmetric profile delivers an optimal combination of capacity and power. Rotor speed range: 15 m/s to 50 m/s on male rotor tip.

Discharge

Several built-in volume ratios offer a range of pressure ratios meeting specific application requirements.

Gears

AGMA Class 11 Gears allow for a variety of internal gear ratios contributing to design optimization and operation economy.

Casing

Heavy duty double-wall cast iron casing provide for structural rigidity, pressure integrity and low noise.

Drive Adaptor

Available drive adaptors (flywheel adaptors or base mounted) offer a convenient means to match up the air end with the drive unit.

Shaft

The steel input shaft can be easily adapted/coupled to the driver with a variety of methods: keyed fit, mechanical locking or shrink- t coupling hub. Drivers used include natural gas and diesel engines; 1800 rpm, 2100 rpm motors; and variable speed drives.

Bearings

The anti-friction bearings are manufactured from all-steel (no plastic or “yellow metal” cages) construction for superior durability. Tapered roller bearings absorb thrust and radial loads; while straight roller bearings handle opposite end radial loads both contributing to the optimal performance of the rotors, even in the harshest of conditions.

Capacity Controls Options

Capacity controls are an option offered on several models. These controls allow gases that have been only slightly compressed to bypass back into the suction head. Capacity can be manually adjusted or automatically controlled based on pressure signal.

Warranty

Sullair Drill Compressor air ends are warranted for two years against defects in materials and workmanship.

20/12 Series Drill Compressor Kit- Optional

- Inlet control valve (Poppet or Butterfly valve assembly)

- Fluid filter

- Oil stop valve

- Housing drive adapter SAE FLYWHEEL ADAPTER OR NO

ADAPTER. - Coupling assembly

- High temperature shut down switch

- Discharge check valve if required

- Inlet filter ( fillter only shipped loose )

- Separator element

- Separator fluid return line w/sight glass

- Minimum pressure check valve

- Fluid thermal valve

- Pressure relief valve

- Running blowdown valve & shut down blowdown valve

- Coalescing control line filter

- Regulator panel assembly (350 & 500 PSI)

- Loose regulator (low pressure)

Two Stage Rotary Screw

Sullair is a leader in supplying compressed air solutions to the major global OEM market place. Sullair drill products are used around the world in such applications as Oil and Gas Exploration, Water Wells, Geothermal Energy Access, Monitoring/Environmental Drilling, Rock Drilling for Blasting. Sullair’s wide range of Drill compressor products supports the drilling market with proven reliable compressed air solutions.

Technical Specifications

| Model | 20/12 Series 600-900 |

| Capacity (cfm) | 600 to 900 |

| RPM | 2100 |

| Rated Pressure (psig) | 350 |

| Approx Weight (kg) | 998 |

| L x W x H | 47" x 34.8" x 42" |

Dear,

How much horsepower is needed from an engine to drive this compressor.

The Sullair 900CFM/ 350 PSI Compressor

Best regards,

Marvin Haakmat